The APEX range of sputter sources have been designed in house by DCA to be the benchmark high performance UHV sputter magnetron for research applications. Currently with two magnetic arrays to accept 2″ and 3” targets, with a wide range of upgrade options including in-situ tilt, power supplies and shutters. APEX can be installed in our forthcoming CAMBR450 PVD sputtering system and integrated into any DCA cluster tool or existing sputtering system. We also offer APEX as a source only for self integration.

Why use UHV Magnetron Sputtering?

- Materials with very high melting points are easily sputtered

- Sputter deposited films have a composition close to that of the target material, ideal for complex compounds

- Sputtered films typically have a better adhesion on the substrate than evaporated films.

- Rates are typically higher than for MBE

What gives APEX-3i its unique performance?

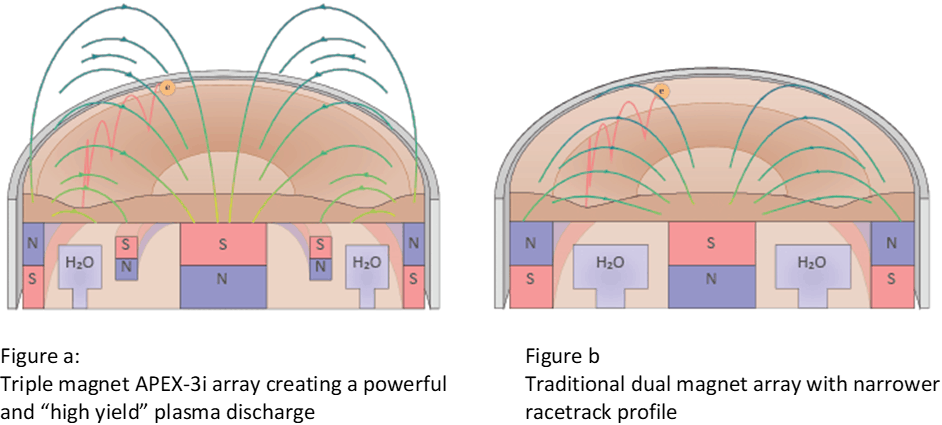

The APEX-3i magnetron includes a unique Triple magnet design, with centre magnet and inner annular ring magnets and outer annular ring magnet. All other competitor UHV magnetrons use a dual magnet design.

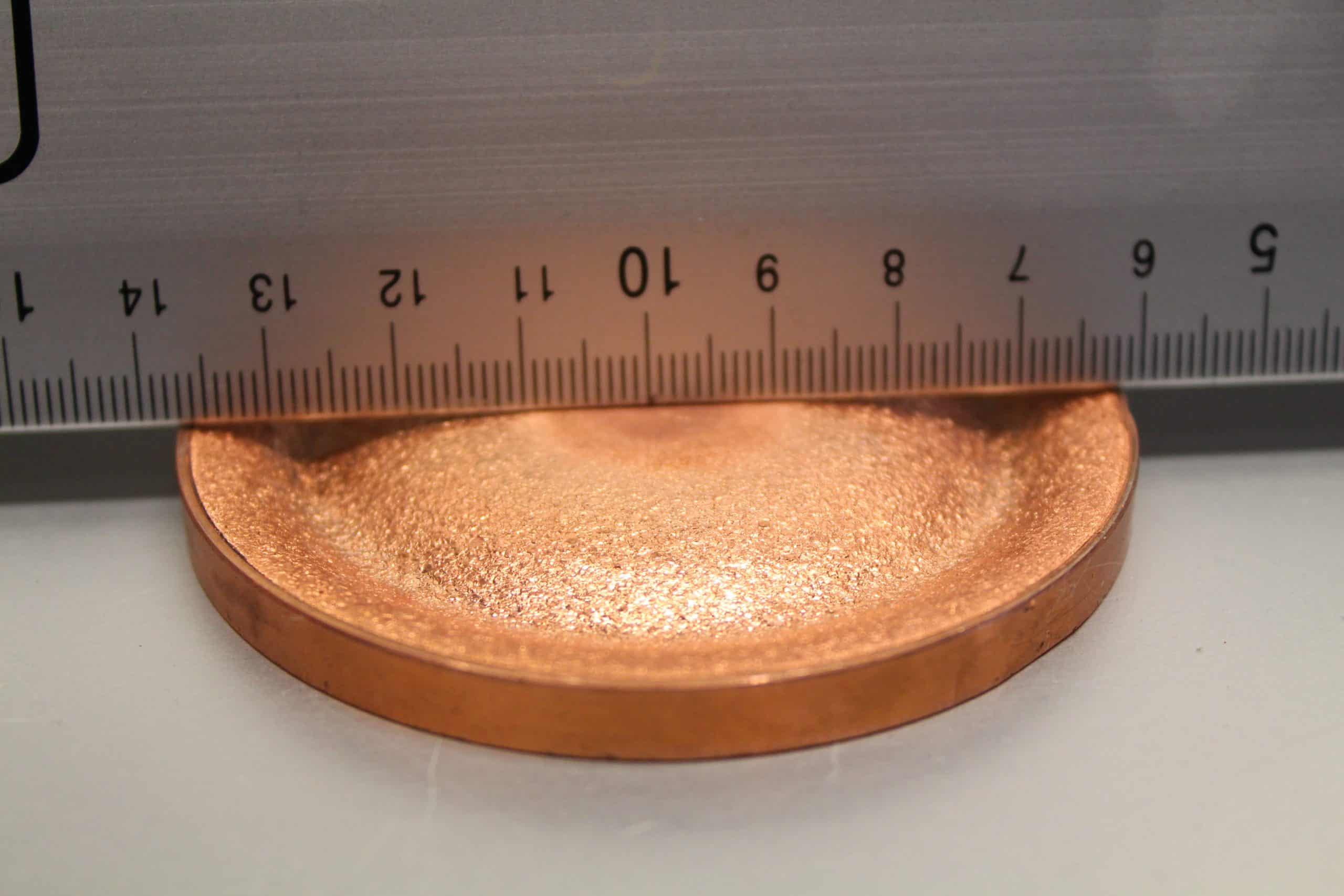

A Triple magnet array ensures the magnetic field lines above the target are near horizontal for a wider area of the erosion profile. A broad erosion profile, in its turn increases the target utilisation, reducing laboratory costs and venting cycles to replace targets. Typical target usage for APEX-3i is a market leading >42%

In addition the diameter of the peak racetrack depth is larger and closer to the edge of the target. The diameter of peak racetrack depth of APEX-3i is ~15% larger than the 46-50mm for a dual magnet 3″ magnetron. A wider racetrack diameter makes the effective cathode diameter larger and improves film uniformity for a given parameter set.

- All metal and ceramic construction, bakeable to 200°C

- Optimised for magnetic targets and high rate sputtering

- Best in class target yield >42%

- 15% wider “virtual” target for improved film uniformity