Oxide Epitaxy

Oxide thin film materials will play an important role in the coming years. A large research effort has been dedicated in growing and combining oxide films and structures. The interest in oxide deposition technologies is fed by the limits that standard Silicon technologies are approaching (high-K material research) and by the wide range of useful properties that oxides exhibit (conductivity, dielectricity, transparency, optical non linearity, ferroelectricity, high Tc-superconductivity, colossal magneto-resistivity, quantum para-electricity and giant piezoelectricity).

Multi-element, complex oxides represent a vast class of materials with rich physical properties. New functionalities can be obtained on the interfaces between different oxide layers with potential applications in electronics, spintronics, optics, sensors, and energy. Complex oxides span a wide range of crystalline structures and play host to a large variety of physical phenomena. High dielectric permittivities, piezo-, pyro-, and ferroelectricity are just a few of the functionalities offered by these materials.

The potential for applications of the more exotic properties like high temperature superconductivity and colossal magnetoresistance is still waiting to be fully exploited. The structural quality of oxide heterostructures now rivals that of the best conventional semiconductors.

DCA oxide MBE systems have been the choice for many leading laboratories involved in oxide thin film research.

Semiconductor Nanostructures and Novel Devices

The novel semiconductor nanostructures such as nanowires and quantum dots are an exciting and expanding field of research. Semiconductor materials often change their electrical and optical properties dramatically when the material dimensions are reduced to the nanometer scale.

The semiconductor nanostructures provide unprecedented levels of functionality in building devices for electronics and optoelectronics applications. The nanoscale devices are being used to study new physics in low dimensional systems. New technologies based on nanostructures are being developed in key areas, such as, communications and information processing, sensing and renewable energy as well as biomedecine.

DCA MBE systems are at the forefront of semiconductor nanostructure research in many leading laboratories in the world.

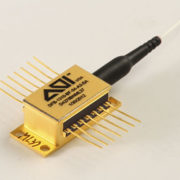

Semiconductor Laser Research and Production

After 50 years of development semiconductor laser diodes dominate the laser market. Semiconductor lasers, or laser diodes as they often are called, are by far the most ubiquitous of all lasers. The diode lasers are used in optical fiber communications, optical storage, printers, medical treatment therapies, scanners and sensors etc. High-power laser diodes are used in industrial applications such as heat treating, laser brazing, cladding, welding and for pumping other lasers.

Continuing extensive research allows diode lasers to break into new wavelengths and new applications. Diode lasers are expanding into shorter wavelengths as well as also making inroads into the longer-wavelength mid- to far-infrared regime. MBE is the most versatile technology for diode laser research and development.

DCA P600 system is extensively used for laser research and development. The production version of this system is used for the manufacture of analog and digital lasers for fiber‑optic networking products. The P1000 4×4″ production MBE system is used for the growth of InGaAs/GaAs/GaAlAs quantum well lasers.

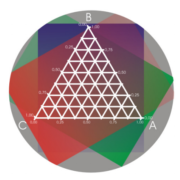

Combinatorial Thin Film Deposition

In combinatorial thin film deposition thousands of different compositions can be synthesized in one deposition run to be screened for desired physical properties. Combinatorial thin film deposition libraries have been prepared using discrete, sequentially masked depositions and co-deposited composition spreads.

DCA has designed and built several combinatorial deposition systems using molecular beam epitaxy (MBE), UHV evaporation and UHV sputtering techniques.